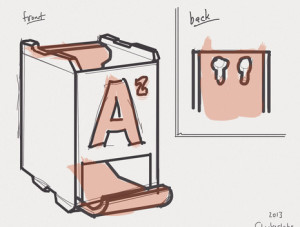

I’m fortunate to get to play with technology at home and at work. Part of product development includes prototyping objects. 3D printing is especially cool because the prototype itself can be sold, particularly if it has obvious utility. I was scrounging around my house, looking for a few AA batteries, and frustrated that my off-the-shelf battery holder from Amazon only held a few of each type. The Amazon holder limited me to buying a product that didn’t serve my needs and forced me to buy more to hold a reasonable number of batteries. Not to mention that it was quite ugly. I realized I could solve this issue right at home. I sketched up a few concepts until I realized one that worked.

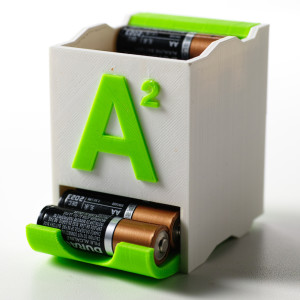

It’s amazing to me how fast I can work with the entire prototyping chain in my office – my home office! The entire development cycle, from concept to product, took about 24 hours. The finished “home” product was a AA version in white and green.

I eventually posted it here on Etsy.com where we got a few sales. We developed two more common sizes (AAA and C) and put those up on Etsy as well. We also published the project here at Quirky.com. While it’s certainly viable as a product straight from the 3D printer, we think it’s also a pretty good candidate for mass market. Scaling a product like this can be expensive so Quirky represents a really great opportunity to get direct consumer feedback as a prototype and, if selected, scale with an experienced partner.

The design iterations happened in a really user-centered way. We realized quickly that a holder alone was nice (if it was attractive and held a fair bit) but the ability to choose which types of batteries – and how many! – was even more important. We altered it to be easily stackable and improved the wall mount design. For the 3D printed version, we bind the whole thing together with high heat glue (which is almost as hot as PLA or ABS in 3D and creates a great bond).

The whole project was a good reminder that development doesn’t have to be expensive, long, or complicated and that our better ideas come from a source of environmental inspiration.